Precision Metal CNC Lathe Machine Ck6140 Horizontal Flat Bed CNC Turning Lathe

Siemens Flat Bed Cnc Lathe Price CK6140 Horizontal Automatic Turning CNC Lathe Machine This series of machine tools is a

Basic Info

| Model NO. | Ck6140 |

| After-sales Service | 1 Year |

| Warranty | 1 Year |

| Type | Horizontal Lathe |

| Processing Accessory | Chuck CNC Lathe |

| Guide Rail | Horizontal Guide Rail |

| Tool Holder | Single-tool Holder CNC Lathe |

| Power Source | Hydraulic Pressure |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | CE |

| Condition | New |

| CNC Lathe | Flat Bed CNC Lathe |

| Max. Swing Over Bed | 400mm |

| Max. Swing Over Slide | 240mm |

| Max. Processing Length | 750mm(Optional:500/1000/1500) |

| Transport Package | Packing in Seaworthy Wooden Cases |

| Specification | Dimension(L*W*H): 2200*1160*1620 |

| Trademark | DRC |

| Origin | China |

| Production Capacity | 500 |

Product Description

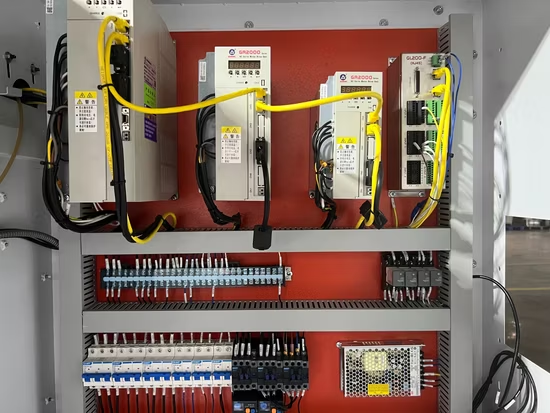

Siemens Flat Bed Cnc Lathe Price CK6140 Horizontal Automatic Turning CNC Lathe Machine This series of machine tools is a mature product mainly exported by Dalian DRC Machine Tool The whole machine has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.Optimized design of the headstock, suitable for turning of disc and shaft parts. It can process straight, arc, metric and inch threads, and multi-threaded. It is suitable for turning discs and shafts with complex shapes and high precision requirements. Parts Processing.Both the machine tool guide rail and the sliding saddle guide rail adopt hard guide rails of special materials, which are super hard and wear-resistant, durable, and have good machining accuracy retention after high-frequency quenching.Adopt domestic famous ball screw and high-precision screw bearing.Each lubrication point adopts a forced automatic lubrication device for fixed-point and quantitative lubrication of the lead screw and guide rail. When there is an abnormal state or the amount of oil is insufficient, a warning signal is automatically generated.The guide rail is equipped with a scraping device to prevent the guide rail from being corroded by iron filings and coolant, and to facilitate the cleaning of the iron filings.

| Model | CK6140*750mm (GSK980TC3 system) |

| Processing ability | Unit ( mm ) |

| Max. swing over bed | 400 |

| Max. swing over slide | 240 |

| Max. Processing length | 750mm(Optional:500/1000/1500) |

| Travel | |

| X/Z axis travel | 280/750 |

| Spindle nose | A2-6 |

| Spindle | |

| Spindle bore diameter | 82 |

| Pull tube hole diameter | 65 |

| Spindle inner hole taper | 40° |

| Spindle series | stepless |

| Max. spindle speed | 150-2000 rpm |

| Workpiece clamping mode | Manual chuck K8-200 |

| Main motor power | 5.5/7.5 kW |

| Feed turret | |

| X/Z axis torque | 5/7.5 N.m |

| X/Z axis rapid speed | 6/8 m/min |

| Turret type | Electicity |

| Tool shank size | 20×20 |

| Turret repeatability | ≤0.004 |

| Tailstock | |

| Tailstock diameter | 60 |

| Tailstock travel | 100 |

| Tailstock center taper | Morse 4# |

| Others | |

| Machine net weight | 1800kg |

| Machine dimension(L×W×H) | 2200×1160×1620 |

| Power supply(power/ electric current) | 11kW/20A |

| Standard configuration | |

| Chuck | Ф200 manual chuck |

| Tailstock | Manual tailstock |

| X axis ball screw | Domestic(Qishan)FD3210-889-1035 |

| Z axis ball screw | Domestic(Qishan)FD2506-407-530 |

| Electricity turret | 4 position |

| X,Z axis screw bearing | Domestic(Derun) |

| Spindle bearing | Domestic P5 |

| Machine casting | Highquality resin sand casting |

| Spindle assembly | Assembly spindle |

| Oil paint | Can be customized color |

| Lubrication | Domestic |

Send to us